Eurotech Xtreme CNC

Swiss Turn Machine

LIMITED TIME OFFER

The New Xtreme SwissTurn CNC - Limited time offer = FREE LNS 12' Magazine Barfeed (SN542)

MORE PROFIT WITH MORE TOOLS, MORE HP & MORE CAPABILITY!

Benefit 1

360° B axis with 8 stations to machine on main or sub spindle. Hybrid = Xtreme Swiss Turn can run with or without guide bushing to allow for small remnants and can run with standard bar stock.

Benefit 2

The Hybrid Xtreme Swiss Turn CNC has an extremely powerful 10 HP main and 10 HP sub, plus a rigid design that allows them to turn and mill tough materials.

Benefit 3

With 33 tool stations you can machine complex parts in one operation or run several simpler parts with no changeover.

Eurotech's New Hybrid Xtreme CNC SwissTurn

machine has greater capacity than the competition

-- up to 42mm bar; and, for a limited time,

comes with a FREE LNS SN542 Barfeeder.

Complex parts in one operation on Eurotech Xtreme

Benefit 4

This Hybrid Xtreme CNC Swiss Turn offers a capacity of up to 42 mm!! (or choose 32 mm or 23 mm).

Benefit 5

The Hybrid models come with a Mitsubishi 700 control, 3 year warranty on parts and labor.

Benefit 6

They come standard with all the tool holders, chip conveyor, and a host of control features. Run on fixed collet or guide bushing.

Benefit 7

Run on fixed collet or guide bushing.

Hear From our Users

“We chose the Eurotech CNC Swiss Turn because it had more technology and was priced very competitively. It had a compact size and took up minimal floor space, and it came with Eurotech’s free lifetime training and guaranteed satisfaction. In addition, we really liked the hybrid feature that gave us the quick change from guide to non-guide bushing, as well as the live tool capacity.”

"The Eurotech CNC Swiss Turn solved our manufacturing problems, eliminated handling, improved accuracy and saved 37% in our cycle time. We now machine parts in one operation and with the free training are still increasing our productivity.”

"The local service team from Eurotech’s distributor, Kansas Oklahoma Machine Tools, Inc. (KOMT), coupled with Eurotech’s Free lifetime training were a big plus in the decision process. The machine was working great and the training was excellent. We were in production the same week of the installation and are still learning and increasing productivity each week."

-MARK LESTER, PRODUCTION MGR., COLEMAN

“A few years ago we had acquired a used Eurotech Swiss Turn CNC machine. This machine has performed so well and the local service and support we receive from U Tech CNC has been so good that it made our choice easy. We decided to purchase a new SwissTurn from Eurotech.”

With Eurotech’s Swiss Turn CNC machines, we are able to accomplish an outstanding surface finish and hold tolerances of 0.0002 on our parts. Thanks to the stability of the machines and the magazine bar-feeder, we are able to leave the machine running unattended for long periods of time. Plus, the machine can do parts to 42mm which is a big advantage over the competition.”

“Furthermore with Eurotech’s SwissTurn CNC Hybrid capability, we can run rough or ground bars stock effectively. U Tech CNC’s support and service were outstanding during this transition and they continue to be today.”

-ALEX NASIO, PRESIDENT OF AIOLOS

.

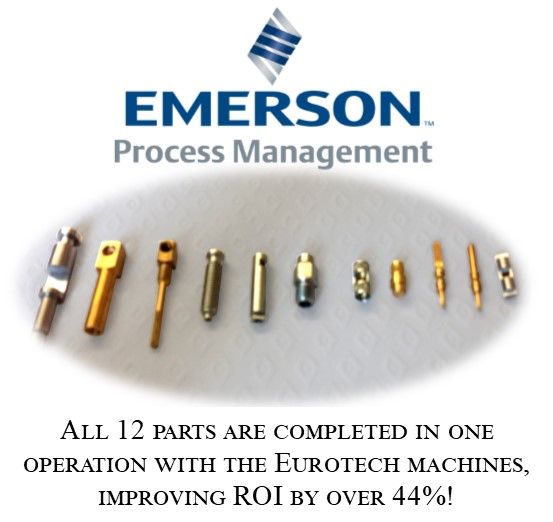

“Previously, all 12 parts were being made in 2-3 operations...we now manufacture them ALL in 1 operation on the Eurotech Swiss Turn CNC machine. Our quality greatly improved and we realized a cycle time improvement of over 44%!” We are seeing perfect parts on the first run and consistent production. Another benefit we’ve experienced is the safety that is incorporated in these machines.”

-RUBEN SALITILLO, ENG. MGR OF EMERSON APPLETON GROUP

“Our search led us to Eurotech SwissTurn CNC machine with 42mm bar capacity. This machine fit our needs perfectly as it could bridge a gap between the swiss style and mill turn style machines and alleviate the workload for both. With the addition of the proprietary B-axis feature, we greatly increased our capacity; for instance, we now have the ability to include parts with angled holes or milled features."

-Brandon Peterson, Shop Manager, Natoma

"The Eurotech Swiss Turn CNC machine was our first machine with the B-axis capability, which allows us to machine the parts in one operation instead of two. This of course is a huge savings in time and improves part quality.

We manufacture 4,000 spray arm tubes a month; with its B-axis capability, this Eurotech machine helped in the production where other machines could not perform."

-Pat Hundley, President, WCM

“One of the reasons we purchased the Swiss Turn machine is that you can only do single operations with screw machines. Now we can finish parts complete and take the burden away from secondary operation areas. This, of course, has translated into a considerable boost in productivity. Not only have we solved a huge bottleneck by making the parts in house with the Eurotech SwissTurn, we have had zero quality defects! We have a 33% cycle time savings and part inspection is down to 1-2 parts per hour. It’s really phenomenal!”

– Dan Anger, CNC Director of Schaeffer Screw Products

Get Case Studies & Brochure on Eurotech Xtreme CNC Swiss

Winning with Technology that Runs Faster, Sleeps Less!

©2017. All rights reserved